Biography

Interests

Anbazhagi Muthukumar*, Shilpa, V. & Muthukumar Muthuchamy

Department of Environmental Science, School of Earth Science Systems, Central University of Kerala, India

*Correspondence to: Dr. Anbazhagi Muthukumar, Department of Environmental Science, School of Earth Science Systems, Central University of Kerala, India.

Copyright © 2018 Dr. Anbazhagi Muthukumar, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Nowadays, the disposal of waste on environment has increased drastically and it is predicted to increase even more in the near future. Waste disposal, has massive environmental impacts and can cause serious problems to the environment. Food waste is considered as one of the major source of Municipal Solid Waste (MSW) globally. Meanwhile, food waste is an organic rich solid waste which has a relatively high energy content, and it seems ideal to achieve dual benefits from energy recovery and waste stabilization. The recent development in the global energy sector is making efforts in turning food waste to wealth, especially in consideration of the global energy security. Several technologies have been developed to serve this purpose, but Microbial Fuel Cell (MFC) shows a very good potential in generation of electricity from food waste, where microbial gel battery can be developed to generate electric current with the help of several chemicals acting as an excellent mediator to encourage the generation of electrical charges. MFC technique can be adopted on a small, medium and large scale applications. Scaling up of this technology, could fetch electrical output by several orders of magnitude, through the connection of an array of biological based fuel cells. In this article, an overview of energy recovery using Microbial Fuel Cell as well as the importance of food waste as a substrate in MFC were mentioned.

Abbreviations

Microbial Fuel Cell - MFC

Municipal Solid Waste - MSW

Introduction

Electricity crisis is a major concern of researchers to seek alternative and sustainable electricity resources for countries, which requires the generation of a large amount of electricity for industrial and agricultural sectors. Meanwhile, several types of research on the renewable and carbon-neutral energy source such as MFC, which is an alternative to an unsustainable and non-renewable energy source (fossil fuels) has been emerging and researchers have allocated efforts towards the development and optimization of MFCs and extended to field application instead of lab studies [1]. In addition, MFC has shown a great potential in generating electricity from food wastes with the help of several chemicals present in food wastes, which can act as an excellent mediator to encourage the generation of electrical charges, where many substrates act as a feed-in MFC for generating electricity including carbohydrates, proteins, volatile acids and cellulose [2]. Studies done by Thi et al. (2015) [3] suggest that, using food waste for electricity generation is apparently a suitable solution for balancing energy demand in many countries, furthermore converting food waste to electricity contributes the lowest investment cost and lowest operation cost while comparing with solar and wind powers, and the use of MFC can assure the reduction of waste in the environment and in waste into wealth conversion, which can adapt by government on small, medium-large scale applications. Scaling up of this technology, the government could fetch electrical output by several orders of magnitude, through the connection of an array of biological-based fuel cells, for multiplying the output the current output several multiple times for any electricity application. Microbial production of electricity may become an important form of bioenergy in future because, MFCs offer the possibility of extracting electric current from a wide range of soluble or dissolved complex organic wastes and renewable biomass contained in the Municipal Solid Waste (MSW) [4].

Microbial Fuel Cell- A Promising Technique

MFC is a progressing technique, which can be used to generate electricity from what we would have been considered as waste. However, as the available conventional waste treatment methods around the globe are very energy intensive for its efficient operation, MFC can serve as an alternative efficient technique, because it requires less energy for its operation, and recover useful energy to create this operation sustainable [5]. Apart from effective waste treatment, MFCs are capable of providing clean energy, so it can be adopted as a sustainable technique for producing electrical energy and treatment of waste, in arresting the issues concerning global environment and electricity shortage. MFC is considered to be a promising sustainable technology in meeting the increasing energy needs and global issues surrounding the waste management and disposal [6].

Thi et al. (2015) have revealed that energy recovery from food waste using anaerobic digestion provided partial energy supply for many countries such as China estimated electricity production as 42.9 TWh/yr. and accounts for sharing 0.87% of total electricity generation, 7.04 TWh/yr. in Japan (0.64% of total electricity generation) and 13.3 TWh/yr. in the US (0.31% of total electricity generation) [3].

History

Potter (1911) [7] has observed the production of electric current through fermentative activity on

organic compounds by yeast and other organisms, and later in the early 1900s, fuel cells have become a

more fascinating device. Furthermore in 1999, especially after the discovery that the mediator was not a

compulsory component, research perspectives of MFC turned much faster [8,9] concept developments

of MFC were discovered by the Barnet Cohen, who created a number of microbial half fuel cell in a 35

unit setup experiment and produced over 35 volts, though only with a current of 2 milliamps in 1931

[10]. The catalyst investigations were done by Karube et al. (1960) who proposed the current design of

MFCs [11]. The study conducted by Suzuki in the late 70s studied the functions of MFC, followed by this

study Bennetto (1990) [12] worked on synthetic mediators resulted in the development of hat analytical

MFC [13]. Subsequently, Lovely and Chaudhuri (2003) [14] have found that Rhodoferox ferrireducens, a

microorganism which is incapable of producing electrons from oxidation of glucose in the presence of Fe3+

in the absence of mediator. Since then, efforts were extended to enhance the performance of mediator-less

microbial fuel cell.

Types of MFC

Two kinds of MFCs were commonly seen depending on the presence or absence of mediators in which

MFC performs; mediators and mediator-less [2]. However the power output can be increased significantly

through electron shuttling by the use of mediators such as potassium ferricyanide, but then the toxicity

and cost of mediators limits development of MFC [15,16]. In 1999, it was found that mediators did not

have to be added to MFC, which was a significant development in MFC, and results in the arrival of a new

generation MFCs and known as mediator-less MFC [17].

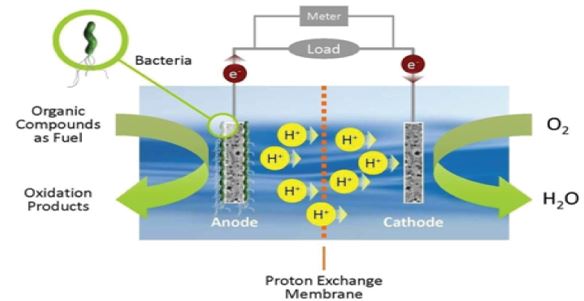

Figure 1 represents the traditional MFC consisted of the anode, where microorganisms actively catabolize the substrate and cathode compartments (two chambers) but there are single chamber MFCs also [18]. The major difference between conventional fuel cells such as methanol fuel cell and proton exchange membrane fuel cell with MFC is biotic electrocatalyst at anode temperature can range between 15°C to 45°C, neutral pH working conditions, complex biomass utilization as a feedstock in anode [19-22].

There are two types of biological fuel cells, namely microbial fuel cells and enzymatic fuel cells. This study deals with Microbial fuel cells and its four configurations only. For the purpose of energy generation, microorganisms can produce electrochemically active substances through metabolism, where fuels are produced in separate reactors and transported to the anode of a conventional fuel cell. In the second configuration, the microbiological fermentation process proceeds directly in the anodic compartment of the fuel cell. Subsequently in the third configuration, electron-transfer mediators shuttle electrons from the microbial bio-catalytic system to the electrode. The mediator molecules accept electrons from the biological electron transport chain of the microorganisms and transport them to the anode of the biological fuel cell. Finally, in the fourth configuration, the metal-reducing bacterium having cytochromes in its outer membrane and the ability to communicate electrically with the electrode surface directly result in a mediator-less biological fuel cell [13,23].

Electron transfer between electrodes to microbial cell results a diminutive way of electron transfer in certain

times. Thus, electro-active groups such as low molecular weight redox species referred to as mediators, may

assist the shuttling of electrons between the intracellular bacterial space and an electrode, and moreover,

mediators are responsible for the redox activity of enzymes present in the microbial cells and also enhances

the electrical communication between the cells and the electrode surfaces [24].

Fe (III)-reducing microorganisms are found to be electrochemically active as they have cytochromes in their

outer membranes, and it was first demonstrated with the Fe (III) reducers, Shewanella putrefaciens, that

these can be used as a catalyst in a mediator- less microbial fuel cell 46-48. Recent studies have demonstrated

that Fe (III) reducing microorganisms of the family Geobacteraceae can directly transfer electrons on to

electrodes. Whereas Metal-reducing bacteria are the most used species in this type of fuel cells [25-27].

Design of MFC

Based on the number of chambers and mode of operation, there are different types of designs are available

for the constructions of MFC, primarily they include single chamber and double chamber. In single

chamber MFCs an anodic chamber coupled with an air cathode, and through that protons and electrons

are transmitted [24]. Figure 2 represents double chamber MFC consisting of one anodic and one cathodic

chamber respectively, and they were separated by an ion exchange membrane [28]. The MFC can connected

with each other in series or parallel assembly, which will referred as stacked MFCs, the connection depends

on the configuration of the electrodes as well as hydraulic flow (Aelterman et al. 2006).

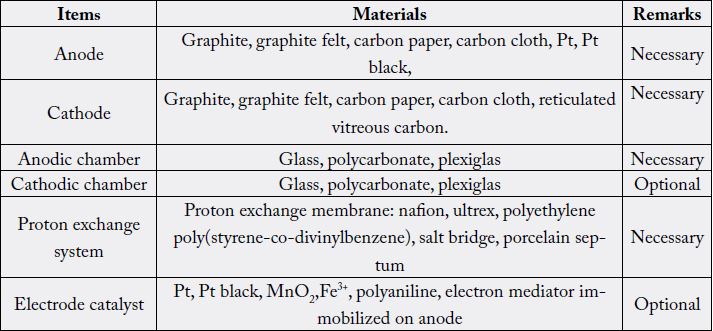

The basic requirements of MFC includes, anode, cathode, anodic chamber cathodic chamber proton

exchange membrane, electrode catalyst (Table 1). Electro chemical oxidation of organic substrates from food

waste using microorganism as a biocatalyst at the anode, results in production of reducing equivalents such

as electrons and protons and allows the electron transfer through external circuit, where electron acceptor

triggers the transfer of electron to anode terminal and act as an electron driving force in the cathode.

Subsequently, protons transferred to the cathode via proton exchanging membrane, which separates anode

from cathode, consequently, electric potential has generated in the opposite direction of electron flow, which

is positive terminal to negative terminal [30-34]. 16kJ of energy has been generating from oxidation of

1g glucose theoretically and 1 kg of food waste able to provide 15.62mol of CH4 (350 L CH4) with a

conversion efficiency of 50%, accounting for an energy output of 13,882kJ and it contributes 3.85kWh of

electricity generation [35].

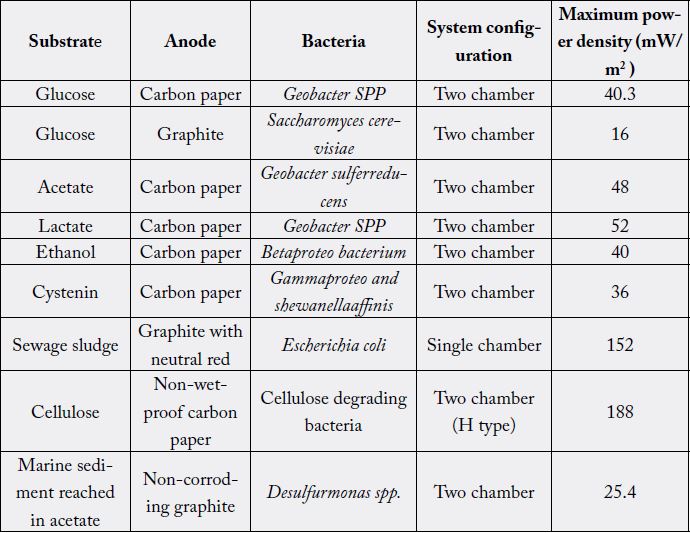

Studies done by Najafpour et al. (2011) [36] has revealed that an oxidizing agent like potassium permanganate had a great ability to increase electric current in MFC. Owing to the peculiarities such as stability in microbial cultures, high electric conductivity, and vast surface area, the anode is usually made of carbon materials containing graphite fiber brush, carbon cloth, graphite rod, carbon paper, reticulated vitreous carbon and carbon felt [37]. Furthermore, performance of MFC greatly promoted by modifications of anode materials (Table 2), where different nano-engineered material have started to use as anode material instead of conventional materials to improve the electron transfer mechanism along with increasing the surface area [38,39], and use of a conductive polymer along with modified carbon and metal-based anode is another feasible manner to improve output electrical power, where attention must be paid to electrode stability [40], and charge balance must be maintained between the anode and cathode for unhindered migration of H+ and OH- during the operation of MFC system, and at the same time, any kind of diffusion should be avoided between electrode compartments, but studies demonstrated that the crossover process is always happening and has been resulting in significant losses in the performance of the microbial bio-electrochemical system [21]. Studies done by Miyake et al. (2003) has revealed that, proton conductivity of Fuel cell will increases by using functionalized hydrocarbon polymer as proton conductive material in polymer electrolyte fuel cell (PEFC), where MFC system has provided the conductivity higher than 0.01cm-1, long-term stability under humid and heated conditions and im-permeability to hydrogen, methanol, and oxygen [41].

Li et al. ( 2016) analyzed the characteristics of organic substrates in food waste before and after MFC treatment to perceive information about how the organic matter was biodegraded and transformed during MFC treatment, and the obtained results show that aromatic compounds in the hydrophilic fraction were more preferably removed than non-aromatic compounds, additionally proteins, aliphatic compounds, tryptophan and aromatic proteins were easily hydrolyzed in MFC, and along with an achieved maximum power density of 5.6W/m(3) and an average output voltage of 0.51V [42]. MFC is not an economical method for routine power generation, since it is incapable of producing as much as electricity that a society required for routine purposes, nonetheless the very first fuel cells produced about 1-40 mill watts per square m (mW/m2) electric current merely [9,43], and in addition, [44] has been reported a produced power up to 3.6 W/m2 from a microbial fuel cell containing a mixed bacterial culture utilizing glucose as a carbon source, which is estimated as fivefold higher power output than the very first fuel cell.

Furthermore, studies regarding the anodic surface area has shown that, the available surface area for bacteria dictates the upper limit of electricity generation, where for providing large surface areas for bacterial attachment and electron transfer to the anode, less expensive methods are compulsory and required to elude the high cost electrode material such as platinum at the cathode and costly ion-exchange membranes to make the technology economical for routine power generation [45].

Factors including rates of substrate oxidation, electron transfer to the electrode by microbes, the resistance of

the circuit, and proton transport to the cathode through the membrane, oxygen supply and reduction in the

cathode have greatly influenced the performance of MFC [46]. Major limiting factors for the generation of

electricity in MFC includes, high internal resistance, and high cost of membranes, consequently it hinders

the practicability of MFC for scaling up, therefore appropriate optimization is needed to make the microbial

fuel cells suitable to produce a bulky amount of electricity for nationwide use [28,47].

One of the important challenges in MFC is recognizing materials that maximize the power generation and columbic efficiency at the same time, minimizes expenses. Various studies have been made for developing suitable and effective electrode material and from literature feature ensuring ideal electrode material includes, good electrical conductivity and low resistance, strong biocompatibility, chemical stability and anti-corrosion, large surface area; and appropriate mechanical strength and toughness [37]. However the surface area of the cathode has an irrelevant role in the production of electricity, but high surface area materials or granular materials such as graphite is worthy to increase cathodic efficiency, and usually obtainable cathodic materials including carbon paper, carbon felt, carbon brush, carbon fiber, graphite of various types and Platinum [48]. In addition, the power output of MFC could enhance by raising the air pressure of the cathode, if controlled oxygen diffusion to the anode is provided [49]. In addition, Bio-cathode has been developed, where cathodic reactions are catalyzed by the help of microorganisms, to overcome the necessities for catalysis through oxygen oxidation on the cathode and moreover it helps to increase the cathodic performance in MFC [50].

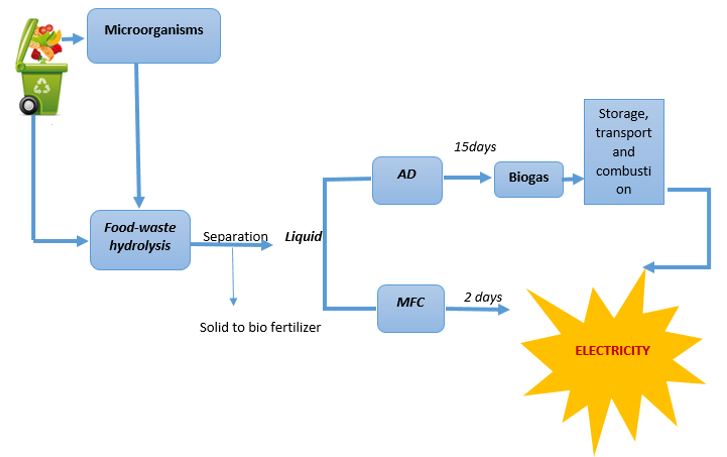

Figure 3 portrays the efficiency of MFC technique over anaerobic digestion. Electric energy production

from food waste developed by incorporating both the ultra-fast hydrolysis and microbial fuel cell is an

efficient method, where the food was first hydrolyzed by using fungal mash rich in hydrolytic enzymes

in-situ produced from food waste. The separated solids produced after the process were readily converted

into bio-fertilizer, though the liquid fed to MFCs for the direct electricity generation with a conversion

efficiency of 0.245kWh/kg food waste. An estimated 192.5 million kWh of electricity produced annually

in Singapore using this method, accompanied by 74,390 tons of dry bio-fertilizer. While comparing the

anaerobic digestion method, on the basis of electricity conversion efficiency and production cost, this method

is more environmentally friendly and economically viable [51].

Ways the MFC Can Improve the World (Applications)

The many applications of MFCs will help to reduce the use of fossil fuels and allow for energy gain from

wastes. MFC technology does not have the power to change the world single-handedly; microbial fuel

cells will never be able to produce enough electricity to take the place of a coal-fired power plant. They will,

however, help to bring the world to becoming a sustainable and more environmentally-friendly place. MFC

can find applications in various fields, for instance, if an MFC could produce 25mW of power, it would be

suitable for cardiac stimulation (Clytonbetin, 2006) [52].

Microbial Fuel Cell has many applications as an alternative source for the energy production, from waste,

generally, MFC uses the metabolic activity of microorganisms for the energy production [5]. MFC can be

used to produce bioelectricity, which uses the organic carbohydrate substrates obtains from what we would

have been considered as waste to generate electricity, also it has an advantage that it directly converts the

fuel molecule into electricity without the production of heat [28]. Logan( 2004) in his study revealed that

the power output of 250-500 and 10-50Mw/m2 has been generated using substrates such as glucose and

wastewater respectively [45]. Usually MFC uses the metabolic activity of microorganisms for the production

of electrons and the electron mediator helps in their transfer, but bacteria’s like Rhodoferax ferrireducens are

capable to oxidize glucose to CO2 without need of an electron mediator to move them to anode,

Thus, this eliminates the requirement for an electronic mediator thereby providing a way for future modifications in the MFC design increasing its efficiency [14]. MFC technology can also serve to the construction of bio-batteries, and which can be used for charging appliance and devices which consumes small voltage, therefore the modification in basic design and development of MFC carries a new way for producing a large amount of electricity from renewable resources [24].

MFCs finds more applications in remote power generations, studies reveal that construction of MFC in

remote regions of Africa offers cheap accessible power to the people in poor African countries. 74% of the

population lives without electricity in Africa, where simple homemade MFC can able to produce electricity

that will enough to recharge a cell phone battery. Lebone Solutions Company created a simple MFC that

is easy to build using materials such as soil, manure, copper wire, buckets, and graphite cloth that will help

to recharge the cell phones [53].

Study conducted by McAnulty et al. (2017) [54], explained that the use of MFC along with a synthetic

consortium, which consisting of an engineered archeal strain to produce methyl coenzyme (M reductase)

for producing methane as well as concealing acetate, in addition, available microorganisms such as Paracoccus

denitrificans from methane acclimated sludge to enable the electron transfer, and also, Geobacter sulfurreducens

helps to produce electrons from acetate, where the processes altogether helps to generate electrical current.

Instead of producing bioelectricity, MFC technology can be modified to harvest bio-hydrogen, where the

generation of hydrogen gas in MFC occurs when an increased aniodic potential has provided with an

additional voltage of 0.23V and besides it needs an anoxic condition at the cathode [55,28]. In addition, the

fermentation process of food substrates can help to the production of hydrogen and it can be linked to MFC

for the generation of electricity (Mohan et al. 2008).

In addition, MFC needs to be added by an external power source when used for hydrogen production to get over the energy barrier of turning all of the organic material into carbon dioxide and hydrogen gas. By keeping both the chambers anaerobic and supplementing the MFC with 0.25 volts of electricity to a standard MFC can be switched to hydrogen production, and the hydrogen bubbles formed at the cathode can be collected and used as a fuel source. Conventional production of hydrogen needs 10 times the amount of energy as an adapted MFC, making the MFC the most efficient and environmentally-friendly way to generate hydrogen for use as a fuel [55-57].

MFC technology can be employed in wastewater treatment, by using several substrates available in the

effluents, the treatment process, as well as the generation of electricity, depends on the ability of microbes to

oxidize the substrates [58]. Food processing wastewater can be employed in MFC for the effective treatment

along with electricity generation, in which the development of cathode significantly affects the performance

of MFC [59].

MFC technology was efficaciously using for the wastewater treatment since early 1991, where 90% COD can be removed using this technique along with columbic efficiency as high as 80% [60-62]. Simultaneous production of methane and electricity from waste materials using MFC is suitable for high-strength wastewaters [63]. Researchers have reported that MFC technology can be prevalently used as a credible and highly cost-effective method to remove nitrogen and organic matters from leachate as well as salinity removal [16,64,65].

Rabaey (2006) demonstrated that specific microbes were excellent sulfide removers in MFC [43]. Kim and others 2008 demonstrated MFC based technology which accelerates the rate of removal of odor when the electricity generation reaches a maximum of 228mW/m2 [66]. Thus MFC could be an efficient method of electricity generation along with odor removal. A novel MFC-membrane bioreactor (MBR) for the treatment of wastewater has recently been reported to achieve a maximum power density of 6.0 W/m3 [60].

Breweries are ideal for the implementation of microbial fuel cells because the wastewater composition

from brewery manufacturing can serve as a good feedstock in MFCs. Organic compounds present in the

wastewater can serve as an excellent nutrient for the growth of microorganisms, so the constant conditions

allow bacteria to adapt and become more efficient. Recently, Fosters, an Australian beer company, started to

produce electricity and clean water as a by-product of brewery waste water. Previously they installed a small

scale MFC for brewery wastewater treatment, and later on developed an advanced MFC system, where

twelve MFCs placed parallel for the production of electricity as well as clean water. In collaboration with

the University of Queensland, Fosters’ plans to improve the MFC’s cleaning power and electrical output and

eventually build a 660 gallon, 2 Kilowatt MFC that cleans all of the company’s wastewater [56].

In addition, the electricity production from sewage wastewater via MFC is another promising application,

where the microorganisms decompose the organic material present in it, and the studies show that the

80% of the organic matter can be removed from sewage wastewater using this method. The processes are

similar to that of brewery wastewater treatment. Pre-treatment of wastewater is required for all the MFC

operations. Furthermore, the electricity production from MFCs will help to offset the high costs of processing

wastewater as well as reduces the disposal of wastewater from industries into oceans and rivers [67,68].

An adapted MFC has been developed for removing dissolved salts from seawater and brackish water to

make the water as potable water, where a third chamber has been introduced in between two electrodes

of standard MFC for filling the sea water. The estimated result of 90% Salt removal efficiency have been

recorded in laboratory work, but much higher removal efficiencies are required to produce drinking-quality

water.

Batteries have restricted lifetime and must be changed or recharged, therefore MFCs are suitable for

powering electrochemical sensors and thus the technology can be used as sensor for pollutant analysis and

process monitoring, where setting up of appropriate cathodic and anodic reaction is the prominent step in

the designing of the technology [17,69]. It is possible to use MFCs as biological oxygen demand sensor

[45]. Different types of enzymatic glucose sensors have been developed [70]. Also, a potential of remediating

toxicants, such as phenols and petroleum compounds is another application of MFC (Morris et al. 2007)

[71]. Biological electricity from wastes produced on board a spaceship is also a possible applicability [28].

MFC also finds application in low- power sensors that collect data from remote areas. Studies were done

in Palouse River, Washington by replacing traditional wireless thermometer with MFC, and the system

is integrated into the riverbed. The whole system representing MFC integrated sensor consist of cathode

attached to an anode by a metal wire, where the anode in the anaerobic sediment of a river or ocean and the

cathode in the aerobic water right above the sediment. A current is generated in the presence of anaerobic

bacteria that naturally grow in the sediment, thus produced current is enough for charging the capacitor to

store energy for whenever the sensor needs it. While comparing the traditional batteries MFC has a longer

lifetime consequently, the sensor can be left alone in a remote area for several years [56].

MFCs can be used for cleansing lake and river water containing organic pollutants such as toluene and

benzene, compounds found in gasoline. Some alterations in the design of MFC offers floating MFC over

the water body, where anode submerged in the water where organic pollutants feed the bacteria while the

cathode floats on top of the water, as a result, the organic pollutants decomposed to carbon dioxide and

water [72].

Importance of MFC Technology

The current argument on fossil fuels and their subsequent effects to the environment has created serious

issues to the global energy societies. However, among the focus of the global energy sectors is to diversify

different methods of energy conversion, MFC provides a sustainable and environmentally friendly manner

for electricity generation [28]. Apart from effective waste treatment, MFCs are capable of providing clean

energy, so it can be adopted as a sustainable technique for producing energy and treatment of waste, in

arresting the issues concerning global environment [6]. As an alternative energy source, MFC will help for

the production of electricity, hydrogen, methane etc. in a sustainable way, thus, generally MFC technology

aims to produce energy from waste by using microorganisms as a catalyst without causing damage to the

environment [24].

Food Waste - A Sustainable Energy Source

Accumulation and exponential growth of food waste has become a crucial problem today, along with

imposing serious threats to our society like environmental pollution, health risks and scarcity of dumping

land with the increase in global population [73]. Biodegradable waste generated from the various sources

including food processing industries, households, and hospitality sectors is referred to as the food wastes. On

per-capita basis, much more food is wasted in the industrialized world (95-115kg/year) than in developing

countries like sub Saharan Africa and Southeast Asia (6-11kg/year) which corresponds to approximately

1.3 billion tonnes of food waste produced annually and equivalent to one third of the food produced in the

world [74].

Food waste mainly consists of carbohydrates, proteins, lipids, and traces of inorganic compounds; moreover food waste consisting of rice and vegetables, which are abundant in carbohydrates while food waste consisting of meat and eggs has high quantity of proteins and lipids, hence the composition of food waste varies with types of food waste [73]. The food waste mainly generating either from early processing stages of food materials such as production, handling, storage, processing, and distribution or during consumption. Russian Federations are in the top list of producing overall food waste, where India ranks seventh [74]. According to the U.S. Environmental Protection Agency (EPA), food waste represents 14.5% of the MSW stream, and most of what’s generated is wasted.

The loss in edible food mass throughout the part of supply chain referred as food waste, and furthermore,

loss of food takes place either at production, post-harvesting handling, and storage, processing, distribution

and consumption [75].

Vegetable and animal commodities loss

The food can be wasted through the food chain, where the first stage includes the cultivation and production of agricultural yields and during the time, losses can be noted. Usually, there is a chance of occurring mechanical damage and spillage during the period of harvesting. In addition to this, the loss can occur due to poor weather condition as well as the disease condition of crops and animals. Later, during and after the harvesting, processing, storage and transportation of food products result in much more losses. Generally, the processing stage is helpful for the conversion of the food products into edible one, which includes treatment and harvest procedures. The errors in the processing techniques and the limitation of the instrument used sometimes results in the wastage of food. Packaging processes and choice of food packaging materials also play a role in the prevention of waste. The next stage concerns the distribution, where a large amount of the waste is made up of the food that has stayed unsold through compliance with food safety legislation and quality standards, marketing strategies, and logistical aspects. The final stages concur with consumption, which generally takes place in food service locations and in homes. The waste at this stage mainly occur due to the large quantity of food prepared or served, the excess amount of purchased foods, the failure to consume food before its expiration date [76,74].

Serious challenges for the effective management of increasing amount of food waste and shocking report

on food wastage revealed worldwide, developed countries like USA producing more than 43.6 million tons

of food waste each year, the concentration of food waste increased to between 40-85% of total solid waste

generated in developing countries, meanwhile these food waste is an organic-rich solid waste which has

a relatively high energy content, it seems ideal to achieve dual benefits from energy recovery and waste

stabilization. Developing countries like India wastes 67 million tonne of food every year which leads to the

assertion by United Nations Development Programme that, 40% of the food produced is wasted which make

food waste serious societal challenge that requires effective management by adopting standard management

practices to reduce the increasing amount of food waste in world [74].

Hypothetically it has declared that 89.78GJ of heat and 847 kWh of electricity can be produced from one ton of food waste [77]. Developed countries such as Canada and United States of America, found to produce energy output as high as 220kWh/ton for commercial applications, likewise there are thousands of large-scale food waste treatment plants in France, Italy, Germany, Denmark, the United Kingdom, Sweden, the United States, Canada, and Southeast Asian countries [78]. China has generated 195 million tons of food waste annually, and it accounts for the highest amount of food waste generating worldwide and able to produce 42,900GW/h electricity and it accounts for 0.875% of total electricity production in China. In addition, the developed countries such as Germany, Switzerland, Netherlands, and United Kingdom, and Sweden, MFC plants are connected to the current grid for nationwide energy supplies and it may become an important source for bioenergy in future [79].

Food Waste for Electricity Generation

Food waste constitutes the major part of MSW, the conventional method such as disposal of waste into

the land causes serious problem to the environment as well as them produce the bad smell and leachate

polluting [80]. MFC has the potential for generating- electricity by using food waste as a substrate and

helps for the conversion of waste into wealth, usually, the performance of MFC to yield electricity depends

on the available food waste concentration [81]. There are several studies being carried out by using food

waste as a substrate in MFCs, the study done by Miran et al. (2016) [82] proved that use of orange peel

waste in a mediator-less MFC is capable of producing electricity without any chemical pre-treatment.

During the collection and treatment processes of food waste, there will be a chance for producing a large

quantity of leachate, this can be a rich source of organic matters and are able to produce electricity along

with an air cathode MFC [83]. The obtained result from the study conducted by Logrono et al. (2015) [84]

shows that different types of sugar such as monosaccharides, disaccharides, and polysaccharides from fruit

and vegetable waste along with high Andean soils are capable of producing electricity. There are several

microorganisms available in canteen food waste, most of them belong to Geobacter, where the Geobacter

species alone enable to produce electric current directly from food waste, moreover, fermentative bacteria is

essential for the effective performance of MFC [81]. The wastewater that is available from food processing

industry can also use for the production of electricity, studies done by Muthukumar et al. (2014) [85] has

revealed that use of sago wastewater is a viable and sustainable process and the addition of salt in the MFC

can improve the performance as well as electricity generation [86-88].

Conclusion

MFC has great potential for generating electricity from readily available waste and it can be a waste

stabilization method and renewable energy production technique. The use of MFC can assure the reduction

of waste in the environment and in waste into wealth conversion. However, as the available conventional

waste treatment methods around the globe are very energy intensive for its efficient operation, MFC can

serve as an alternative competent technique, because it requires less energy for its operations Microbial

production of electricity may become an important form of bioenergy in future because, MFC offers the

possibility of extracting electric current from wide range of readily available food waste. The usage of food

waste as a substrate in MFC will provide effective waste treatment along with the production clean energy,

so it can be adopted as a sustainable technique for producing electrical energy and treatment of food waste.

Bibliography

Hi!

We're here to answer your questions!

Send us a message via Whatsapp, and we'll reply the moment we're available!