Biography

Interests

Andi Amran Sulaeman1, Ana Nurhasanah2*, Andi Nur Alam Syah2 & Sri Satya Antarlina3

1Ministry of Agriculture

2Center for Agricultural Engineering Research and Development, Tangerang, Banten, Indonesia

3Institute for Agricultural Technology, East Java, Jl. G. Obos Km., Jawa Timur

*Correspondence to: Dr. Ana Nurhasanah, Center for Agricultural Engineering Research and Development, Tangerang, Banten, Indonesia.

Copyright © 2019 Dr. Ana Nurhasanah, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

The sorghum variety of varieties averages 2-4mm in size and contains the outer skin / husk about 30 percent. In the process of milling the skin / husk of sorghum seeds then exfoliated against this husk. So that the process of peel husk can be done evenly so it is necessary grading process / sorting of sorghum seeds so that the seeds obtained sorghum uniform and polishing can be evenly distributed. Addition is to remove the pericarp layer of sorghum and the layer of testa containing tannins from the endosperm, the layer can reduce the digestibility of protein in the stomach and cause constipation. Indonesian Center for Agricultural Engineering Research and Development (ICAERD) has developed a pneumatic type of sorghum grading machine with a working capacity of 200kg/hour. The purpose of this activity is to test the prototype performance of grading machine/ grain of sorghum seeds with main target: (i) Sorting of sorghum seed with uniform seed size; (ii) produce clean sorghum seeds. The performance test of grading machine of sorghum seed is done by method and activity stage which is divided into: preparation stage, manufacturing and modification stage, functional testing stage and performance test, and reporting stage. Sieving machine using 1 HP electric motor drive power and sieve machine dimensions is 1700mm x 740mm x 1240mm. The capacity of grading machine/grading reaches 200kg/hour and the efficiency of sorting/grading of sorghum seed uniform is 86,25%. The efficiency of grading size 4mm is 90%.

Preliminary

Sorghum is one of the food crops that is being prioritized in Lamongan regency because it is a potential

local food material to support food security. East Java is one of the centers of sorghum seed production.

Production of sorghum seeds in East Java amounted to 4,180 tons/ha in 2012, but decreased to 3,898 tons/

ha in 2013, then increased in 2014 (Diperta, 2016). In August 2014 the area of planting sorghum reached

± 509ha consisting of 450ha of paddy fields and 59ha of non-rice field with productivity of about 6tons/ha

(Anonymous, 2014).

According to the East Java Communications and Informatics Office, the potential land for sorghum reaches 10 thousand hectares, but the realization is still recorded 950 hectares, so there is still a great potential for sorghum to be developed again. From the extent of sorghum land in East Java, the dominance of land area of 500ha is in Lamongan regency and the rest spread to other areas (www.lamongan.go.id). In Lamongan regency, sorghum production center is located in Babat sub-district. Data in 2013, the production of sorghum seeds in East Java is highest in Lamongan regency of 1,673 tons, Pasuruan Regency’s production potential is 1,111 tons, while other regencies are: Pacitan (36 tons), Banyuwangi (35 tons), Probolinggo (81 tons), Bangkalan (60 tons), Sampang (212 tons), and Sumenep (690 tons). In East Java for most of the year there is a harvest of sorghum, but in May (Benyuwangi, Pasuruan, Sumenep) and October (Lamongan) (Diperta, 2016). The average national production of sorghum seeds is 5,217 tons [1].

Sorghum is used as a food and animal feed, has a good nutritional content and protein content even higher than rice. The content is calories (332cal), protein (11.0g), fat (3.3g), carbohydrates (73.0g), calcium (28.0mg), iron (4.4mg), phosphorus (287mg) and vitamin B1 (0.38mg) (Leder, 2004).

In sorghum seeds, between the seeds and seeds of the seeds coated by the layer of testa and aleuron. The coat of the testa is included in the skin part of the seed, and the aleuron layer is included in the part of the seeds, the skin of the seed coat is tightly bound by the seed of the seed, through a thin layer called a layer of cement. In the process of grinding, the bonding of seed coat with seed is difficult to separate. The composition of the sorghum seed part consisted of 8% outer skin, 10% institution and 82% seeds (Figure 1). Marcia, 2002 states that the average size of Kawali varieties of sorghum seeds is 3.0-3.4mm with weight of 1000 seeds is 30 grams, whereas Numbu varieties averagely seed size 4,2-4,8mm with weight of 1000 seed is 36-37 grams.

Sorgum contained in Lamongan regency is sorghum KD-4 variety which is sorghum local varieties and has long been cultivated for generations by farmers. This commodity becomes a mainstay of farmers during the dry season because the plant is resistant to the condition of less water. But until now the utilization of sorghum for food needs has not been maximized and still limited utilization for feed and industrial purposes. Whereas the nutritional value of sorghum is not inferior to rice as staple food. Chemical composition of sorghum contains lots of protein (8-12%) equivalent to wheat while rice reaches only (6-10%), and its fat content (2-6%) higher than rice (0.5-1.5%). One obstacle in the utilization of sorghum as food is the high content of tannins that reach 40.79mg/100g [3]. High tannin content, in addition to affecting the taste (bitter), is also malnutrition that can interfere with the process of mineral absorption by the body (Adiandri et al., 2014).

KD4 varieties of sorghum seeds are 2-4mm in size and contain about 30 percent leather / husk. In the process of milling the skin / husk of sorghum seeds then exfoliated this husk. So that the process of peeling husk can be done evenly then it is necessary grading process / sorting of sorghum seeds so that the seeds obtained sorghum uniform and penyosohan more perfect. Addition is aimed at removing the pericarp layer of sorghum and the layer of testa containing tannin from the endospermnya, the layer can decrease the digestibility of protein in the stomach and cause constipation. Indonesian Center for Agricultural Engineering Development (BBP Mektan) has developed a pneumatic type sorghum grading machine with a working capacity of 200kg/hour. Using the grinding machine of sorghum seeds is expected to improve the uniformity of the results and increase the capacity of the milling. With uniform sorghum seeds and uniform size it will occur the perfect process of milling because there is no longer sorghum seeds smaller size that is not lost because of small size so that escaped out of part pengosohan. In this regard, it is necessary to apply a cleaning machine and sieving / sorting / grading of sorghum seeds so as to support better and more uniform milling process so that the degree of whiteness is higher and the tannin level becomes lower.

Materials and Research Methods

This activity is carried out during the period of March 1 until November 2016. The location of planning,

design, manufacturing of machinery, functional testing is done in the Laboratory of Engineering of BBP

of Agricultural Mechanization, Serpong while the verification test and the performance test and field test

are conducted in Patihan Village of Lamongan Regency, East Java. The main engineered ingredients for

the manufacture of grinding machines of sorghum grading include: screen diameter 3, 4, and 5mm, 1Hp

electric motor, iron plate, elbow iron, pulley and belt and other supporting components. While the test

material used is sorghum from KD4 variety. The equipment used consists of a set of supporting tools for

manufacturing activities (drilling machines, lathe, welding, cutting, bending, grinding, etc.), The development

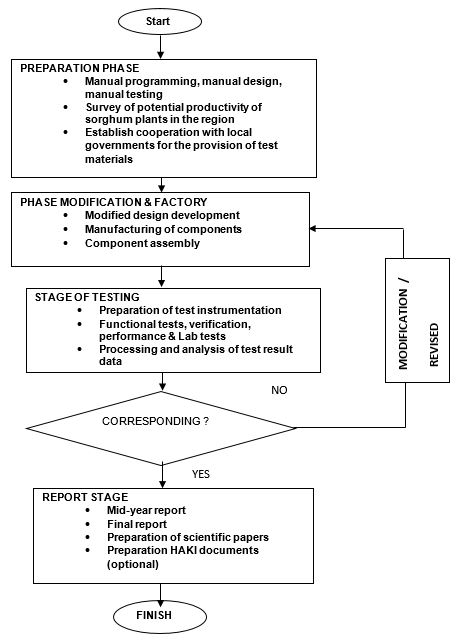

of a sorting machine / grading of sorghum seeds is done by method and activity stage which is divided into:

preparation stage, pre-design stage, design, fabrication, testing phase, and reporting stage. The flow chart of

the methodology like Figure 2 below:

The uniformity of sorghum seeds is required before the mucking is done to obtain optimal capacity for work.

The uniformity of the size of the sorghum seed will affect the length and decrease in quality of the resulting

milling. Therefore it is necessary to add a sorting tool / grading to obtain the uniformity of the material.

The function of the grinding machine of sorghum seeds is mainly to separate the sorghum seeds according to

their size so as to obtain uniform seeds beside it also serves to separate the whole seeds with other impurities

such as the crown and sorghum stalk and the soil and hard rock that are still elbowed at harvest time. This

is to avoid the occurrence of blockages in holes penykoh konkaf and worsening rocks friction due to friction

with hard rocks. Besides this sorting / grading function can also be used to separate the bran / bran that is

still mixed with sorghum seeds sosoh. The sieving design uses a 5mm perforated plate (for seed size ± 4mm)

and measures 4mm (for seed size ± 3mm) and measures 2mm (to separate the bran). The sieving design has

an eccentric type that is driven using an electric motor with a power of 1HP.

Results and Discussion

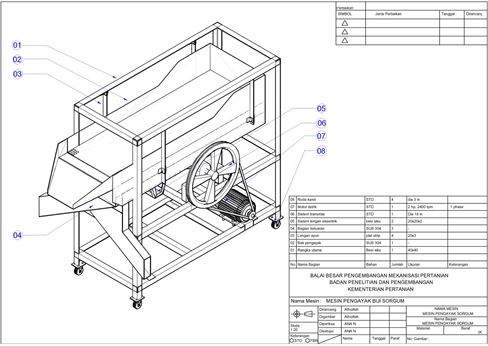

Sieve machine sorghum capacity of 200kg/hr overall has dimensions p x l x t is 1700mm x 740mm x 1240mm

with 1Hp electric motor drive power. This sorghum sieving machine consists of the main components of the

sieving unit, frame and electric motors.

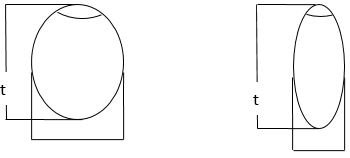

The sorghum sieving machine is designed to obtain sorghum seeds of uniform size. Various sorghum size will be difficult in penyosohan because the seeds are larger will be lost first while the smaller has not been lost. When the large sorghum has been eroded along with the small sorghum, the great sorghum will still be lost again with the small sorghum, which will decrease the yield and prolong the time sosoh. Sievers consist of a main frame made of 40 x 40mm elbow, sieve from 1.5mm 1.5mm, 1Hp electric motor, pulley and V belt to transmit power. The size of the perforated plate was determined based on the mean value of the dimensions of the sorghum seed (Appendix 6) and dimensional measurements were performed by taking samples of 100 seeds randomly (Figure 5). So as to obtain the size of perforated plate with 5mm hole size for sorghum grade ± 4mm (grade 4) and 4mm hole size for sorghum grade ± 3mm (grade 3). In addition to functioning as a separator of sorghum seeds, this sieve can also function as a separator sorghum sosoh still mixed with bran / bekatul. Perforated plate used to separate sorghum sorghum with bran using 2mm hole size. Perforated plates are made knockdown and fitted with bolts to be modified in accordance with the desired rendering. The overall dimension of the sieving machine is 1700mm x 740mm x 1240mm.

The sorghum sieving machine is designed to obtain sorghum seeds of uniform size. Various sorghum size will be difficult in penyosohan because the seeds are larger will be lost first while the smaller has not been lost. When the large sorghum has fallen along with the small sorghum then the great sorghum will still be dumped again with the small sorghum, which will decrease the yield and increase the length of time pengosohan. Sievers consist of a main frame made of 40 x 40mm elbow, sieve from 1.5mm 1.5mm, 1Hp electric motor, pulley and V belt to transmit power. The overall dimension of the sieving machine is 1700mm x 740mm x 1240mm.

The sieving machine performance test was performed using sorghum varieties KD-4, this test to see whether

the size of the perforated plate was in accordance with the characteristics of sorghum seed (dimensions),

speed and sieving eccentric movement adjusted to the required electric motor. Based on the test results,

sievers have been able to separate sorghum into two grades, namely grade 4 for those who did not pass

the 4mm perforated plate and grade 3 for the 4mm perforated plate. The eccentric force velocity has been

adjusted to the material flow rate on a particular incline as well as the force of gravity.

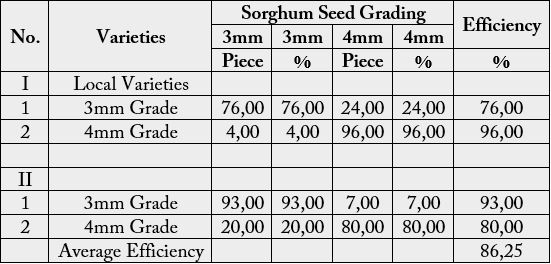

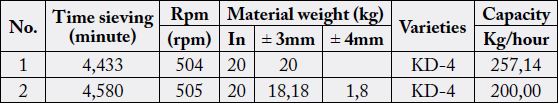

In the performance test using sorghum KD-4 varieties also obtained grade 4 and grade 3 sorghum on grade 3 there is 7% sorghum which has dimension dimension more than 4 mm, this is caused sorghum passing hole in longitudinal position at high side, from Random measurements on 100 seeds were obtained on average for length, width and height respectively 3.27mm, 2.66mm and 3.7mm and efficiency of sorghum seed grade KD4 grade 3 of 93%. In sorghum of KD-4 grade 4 variant there are 20% sorghum which has dimension less than 4 mm in the sense of efficiency of grade 4 sieving sorghum KD4 varieties 80%. The efficiency is smaller because this is due to sorghum not direct contact with the perforated plate, this constraint can be overcome by extending the seed time above the perforated plate so that the possibility of direct contact with the perforated plate is longer and the deviation result can be reduced. Although no sorghum seeds are retained on a perforated plate with a 5mm hole size but this plate is used to separate the panicle stalks, husks and other impurities that participate in the sorghum seeds so that the sorghum seeds enter the waste hopper is clean and does not inhibit the process of milling. In general, the sorghum sieving machine has been able to function properly and can separate the sorghum seeds in grade 3 and 4mm with an overall average efficiency of 86.25%. The capacity of the average sieving machine is 232.55kg/hr as in Table 1 and Table 2 [4-10].

Conclusions and Recommendations

Overall sieving / grading of sorghum seeds have been able to sow sorghum seed well with 200kg/hour

capacity and efficiency of sieving / sorting / grading for KD4 sorghum varieties reach 86.25%.

Bibliography

Hi!

We're here to answer your questions!

Send us a message via Whatsapp, and we'll reply the moment we're available!