Biography

Interests

Dhlamini, B. R. & Van Wyk, J. P. H.*

Department of Pharmacology and Therapeutics, Sefako Makgatho Health Sciences University, South Africa

*Correspondence to: Dr. Van Wyk, J. P. H., Department of Pharmacology and Therapeutics, Sefako Makgatho Health Sciences University, South Africa.

Copyright © 2019 Dr. Van Wyk, J. P. H., et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Used newspaper is one of the major components of solid waste of which millions of tons are produced annually by the global population. Landfilling, besides incineration and recycling, is the most popular process of managing this waste material also described as organic waste. Cellulose, a glucose biopolymer and structural component of newspaper could act as a renewable feedstock for the production of bioproducts if degraded into glucose a fermentable sugar. Cellulase a multicomponent hydrolytic enzyme system from Aspergillus niger has been used to bioconvert the cellulose component of newspaper into glucose. The saccharification of newspaper by A. niger cellulase has been performed during the successive treatment of newspaper with fresh cellulase during ten consecutive incubation periods of 2h each. The amount of sugar released from newspaper during each incubation period has been determined and various sugar releasing patterns at the different incubation temperatures constructed. The total amount of sugar released during the different incubation periods were determined and the percentage saccharification of newspaper at each incubation temperature were determined as, 50% at 40ºC, 64% at 50ºC, 59% at 60ºC and 42% at 70ºC.

Introduction

Paper is an important material, used daily for many purposes worldwide. During 2014 the global production

of paper and cardboard stood at approximately 407 million metric tons. Since paper can be classified as a

renewable resource, recycling is crucial within the paper industry and paper, amongst many materials, has

one of the highest recycling rates. The total global demand for newsprint during 2016 was 23.8 million

metric tons and about 50% of the globally produced paper materials are obtained from recovered resources

with 50% of recovered paper obtained from industry and business [1]. Because of environmental benefits

recycled used paper materials have advantages over disposal options such as landfill and incineration. The

recycling of paper materials also have limitations, as used paper can only be recycled four to six times. Each

time recycling occurs the fiber becomes shorter and weaker and virgin paper has to be introduced into the

paper production in order to maintain the strength and quality of the fiber in the paper material. Through

the blending of virgin paper and recycled paper, recovered paper and forest-based fiber complement each

other ecologically and economically. Eventually used paper such as newspaper becomes part of solid waste

of which incineration and landfill are the most obvious options [2].

Cellulose is a glucose based bio-polymer with the glucose units linked by β-1,4-glycosidic bonds and it is also a major structural component of paper materials [3]. Together with hemicellulose and lignin, cellulose forms part of the cell wall structure and cellulose exist in two forms, an amorphous form and crystalline form with the latter part densely packed while the former is more susceptible to cellulase catalysed hydrolysis and thus cellulose can act as resource for glucose production. Cellulase is a complex enzyme system composed of three enzyme catergories namely endogluconases, exogluconases and β-glucosidases and these three enzyme systems work together synergistically during the degradation of the cellulose into glucose [4]. Endoglucanase catalyzes the hydrolysis of cellulose molecules in the inner part by breaking down the β-1,4-glycosidic linkages at the amorphous sections. Exo-glucanases break down the glycosidic bonds of cellulose molecules at both the reducing and non-reducing ends while the β-glucosidase enzyme hydrolyze the cellulose molecule to glucose units [5].

Globally waste is becoming more problematic since populations are increasing due to civilization [6]. The amount of waste produced in the world is escalating and it is alarming as the organic part of these volumes of waste contribute to global warming. Solid waste is mostly dumped in large volumes in landfills with less waste recycled, burned or incinerated [7]. According to Neelamgam et al. [8], waste paper that is generated annually is more than 400 million tons with newspaper being the most accessible paper to communities and this cellulose containing material ends up as solid waste in most municipalities instead of being used in the value added products such as biofuel generation.

When waste paper such as newsprint becomes part of solid waste, the renewable potential of this paper material is not completely utilized which could thus not be beneficiary to the environment. A. niger cellulase, a multi-component enzyme system has however the ability to degrade cellulose into glucose, a fermentable sugar [9,10]. During the current investigation A. niger cellulase has been used successively to bio-convert newspaper into sugars, mainly glucose. The successive release of sugars from cellulase treated newspaper would also not only supply information on the potential of newspaper as resource for bio-products but would also reflect information of the relative amount of the crystalline and amorphous sections of cellulose present in newspaper.

Methods and Materials

Newspaper was used during the successive cellulase catalyzed bio-conversion into fermentable sugars with

the paper material prepared as circular discs with the diameter 6mm. A. niger fungi cellulase powder was

commercially obtained and prepared as a solution (2mg.ml-1) with 0.05 mol.dm-3 tris-HCl buffer, pH 5.0.

The prepared cellulase solution was kept at 4°C.

Circular pieces of newspaper (20 pieces - 0,03g) were transferred in triplicate into test tubes and mixed with

800μl of tris-HCl buffer (0.05mol.dm-3, pH 5.0) as well as 200μl of the enzyme solution. The stoppered

reaction mixtures were incubated for a period of 2 hours at 40ºC, 50ºC, 60ºC and 70ºC. The cellulase reaction

was terminated by cooling the samples to room temperature where after the cooled samples were centrifuged

at 3000r.p.m. for a period of 10 minutes. The supernatant of each incubation was removed with the sugar

content in each supernant determined. The precipitates were remixed with fresh buffer (800μl) and cellulase

enzyme (200μl) and re-incubated for further 2 hours at various temperatures. The re-incubation was repeated

for 10 successive periods of 2 hours each with the amount of sugar released from the newspaper during each

incubation period, determined.

The sugar content of each supernant after the various cellulase-cellulose incubation periods was determined

according to the DNS method described by Miller [11]. The supernant was mixed with DNS reagent (1.5ml) and the test tubes were placed in a boiling water bath for 10 minutes where after it was cooled to room

temperature. The amount of sugar in each test tube was concluded from the colour intensity of the sample

as read on the spectrophotometer at 520nm. A calibration curve was constructed using glucose standards at

concentrations between 0 and 10mg.ml-1. The calibration curve was used to quantify the amount of sugar

released from newspaper during each of successive cellulase action at the different temperatures.

Results and Discussion

Used newspaper is a major component of waste paper of which millions of tons are produced daily, worldwide

[12]. Currently the most prominent procedure of managing used paper such as newspaper is through

landfilling or incineration. Due to the chemical nature of paper materials it would be of environment

advantage to utilize the renewable potential of newspaper before it is exposed to traditional waste management

procedures. In recovering the glucose content of post-utilized newspaper by degrading its cellulose content

into glucose could assist the process of developing newspaper as a resource for bio-product development

through the fermentation of glucose resulting from the saccharification process.

Cellulose is composed of two structural sections namely a crystalline section [13] and amorphous section [14] with the crystalline part offering most resistance to the enzymatic action of hydrolytic enzymes such as cellulase. The amorphous section is generally more susceptible for cellulase action with the more resistant crystalline section forming the majority component of the cellulose structure. In order to maximize the sugar formation from waste newspaper as well as to conclude the relative crystalline and amorphous components of cellulose in newspaper this used material has been treated successively with fresh A. niger cellulase at different incubation temperatures. The amount of sugar produced during each incubation period at various incubation temperatures has been calculated as well as the average amount of sugar released at the end of all the successive incubation periods.

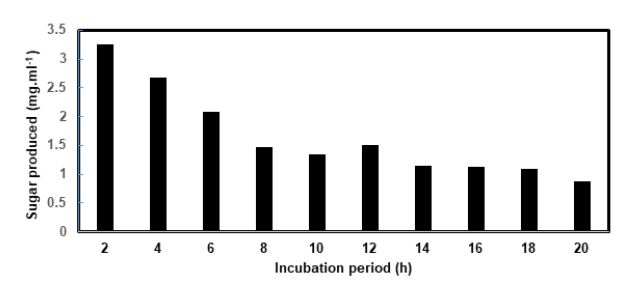

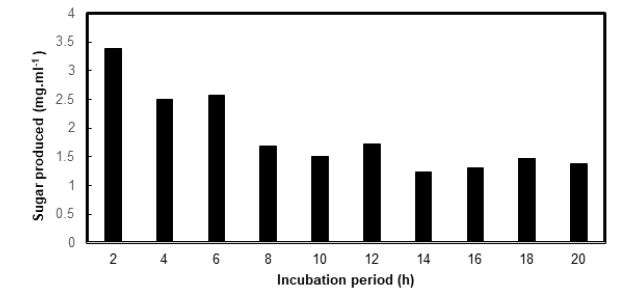

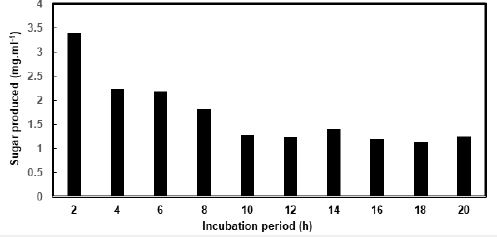

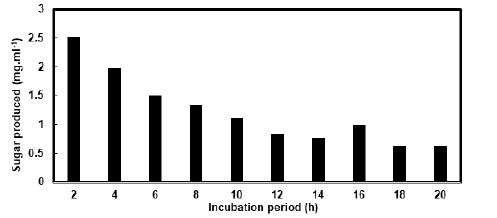

Figures 1 to 4 illustrate the amount of sugar released from newspaper during ten successive incubation periods of 2h each with fresh A. niger cellulase enzyme during various incubation periods. During the first incubation period maximum sugar concentration was produced and the highest amount of sugar released during this first incubation period was obtained at an incubation temperature of 50ºC resulting in a sugar concentration of 3.4mg.ml-1. The second highest amount of sugar released during the first incubation period was obtained when newspaper was treated with the enzyme at 60ºC, producing a sugar concentration of 3.3mg.ml-1. The third highest sugar concentration was obtained during incubation at 40ºC producing a sugar concentration of 3.2mg.ml-1 while the lowest amount of sugar was obtained at 2.5mg.ml-1 during incubation at 70ºC.

Figure 1 shows the general trend of sugar formation during the ten successive periods of newspaper treatment with A. niger cellulase at 40°C. The amount of sugar released during each incubation period decreased and resulted in a sugar concentration of 0.8mg.ml-1 after the tenth incubation period or 20h of cellulase catalyzed degradation. The amount of sugar produced during the last incubation period was 300% less than the amount produced during the first incubation period. The highest rate of decreasing sugar production when incubated at 40°C was observed during the first four incubation periods when the sugar concentration decreased from 3.2mg.ml-1 to 1.4mg.ml-1, a decrease of 230% at a decreasing rate of 0.23mg.ml-1.h-1. During the last six incubation periods (12h) the decreasing rate of sugar production was calculated at 0.05mg.ml-1.h-1. The total amount of sugar produced during the tenth successive incubation periods resulted in an average sugar concentration of 1.6mg.ml-1 indicating a relative saccharification of 1.6%.

When incubated with A. niger cellulase at 50°C (figure 2) the amount of sugar produced from newspaper during the first incubation period resulted in a concentration of 3.4mg.ml-1 that was 6.3% higher than the amount of sugar released during the first incubation period at 40°C. The amount of sugar released during the final incubation period was calculated at 1.4mg.ml-1 that was 1.4 times less than the sugar produced during the first incubation and 71% more than the amount of sugar produced during the final incubation period when incubated at 40°C. The highest degree of decreasing sugar formation at 50°C was also experienced during the first four incubation periods at a rate of 0.26mg.ml-1.h-1 that was slightly higher than the corresponding rate observed during cellulase catalyzed degradation at 40°C. During the last six incubation periods the decreasing rate in sugar production was calculated at 0.12mg.ml-1.h-1. The average sugar concentration obtained during the tenth consecutive period was 1.9mg.ml-1, which resulted in a relative saccharification of 1.9% that was 18.8% higher than the relative saccharification obtained during incubation at 40°C.

The successive cellulase catalyzed degradation of newspaper by A. niger cellulase at 60ºC is represented in figure 3. The maximum amount of sugar produced during the first incubation period resulted in a concentration of 3.3mg.ml-1 that was almost identical to the amount of sugar released during incubation at 40ºC and 50ºC. The amount of sugar released during the last incubation period was produced at a concentration of 1.2mg.ml-1 that was 1.7 times less than the amount of sugar released during the first incubation period. Sugar released during the final incubation period was 50% more than the sugar produced during the corresponding period when incubated at 40ºC and 14% less than the amount of sugar released during the same period when incubated at 50ºC. The decline rate of sugar production during the first 8h of cellulase catalyzed degradation was calculated at 0.18mg.ml-1.h-1 with no significant change in sugar formation during the last six incubation periods. The average amount of sugar produced during these ten successive incubation periods resulted in an average sugar concentration of 1.7mg.ml-1 representing a relative saccharification of 1.7%.

The consecutive saccharification of newspaper at 70ºC with A. niger cellulase is illustrated in figure 4. During the first incubation period sugar was produced at a concentration of 2.5mg.ml-1 that was 52% less than the corresponding sugar yield at 50ºC and 28% less than the sugar obtained during the first incubation period at 40ºC while it was 24% less than the sugars produced when incubated at 60ºC. The rate of decreasing sugar production during the first 8h was calculated at 0.15mg.ml-1.h-1 that was less than the rate experienced during degradation of newspaper at all other incubation periods with the rate of decreasing sugar formation during the final eight incubation periods at 70°C calculated at 0.04mg.ml-1.h-1. The sugar concentration obtained during the final incubation period was 0.6mg.ml-1, 100% less than the amount of sugar released during incubation at 60ºC, 128% less than sugar released during incubation at 50ºC and 33% less than the corresponding sugar concentration produced during the cellulase catalyzed bioconversion at 40ºC. The average sugar produced during the ten successive incubation periods at 70ºC resulted in a concentration of 1.1mg.ml-1 that was the lowest average amount of sugar released from newspaper during saccharification at all incubation temperatures.

The sugar formation during the successive saccharification of newspaper with A. niger cellulase at different incubation temperatures showed the same trend of decreasing sugar formation. This trend confirms the relative amounts of the amorphous and crystalline sections in the newspaper. Most of the amorphous component is saccharified during the first incubation period resulting in a relative high sugar concentration. The lowering in sugar production observed during the successive degradation of newspaper reflects the decrease in relative amounts of amorphous section and the increase in the more difficult to degrade crystalline section. Degradation of newspaper by A. niger cellulase action at 40ºC and 50ºC resulted in the highest average amount of sugar produced at a concentration of 1.9mg.ml-1. This observation was confirmed with the highest amount of sugar produced during the first incubation period which resulted in sugar concentrations between 3.2mg.ml-1 and 3.4mg.ml-1. From this results it can be concluded that optimium saccharification of newspaper by A. niger cellulase could be performed at any temperature between 40ºC and 60ºC. By saccharifying newspaper at 40ºC will have a positive environmental effect as this relative low incubation temperature requires less generated energy for incubation purposes.

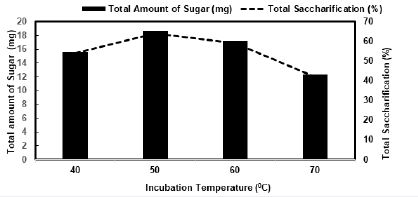

The total amount of sugar released during the ten consecutive incubation periods of newspaper with A. niger cellulase at the different incubation temperatures is reflected in figure 5 which also reflects the total percentage of newspaper saccharification at the various incubation procedures.

The highest amount of total sugar was released during saccharification of newspaper at 50ºC and it resulted in an amount of 18,7mg of sugar that was 9% higher than the amount of sugar released during incubation at 60ºC. This maximum amount of sugar produced was 52% more than the amount of sugar released during bioconversion at 70ºC and 20% more than the sugar produced when incubated at 40˚C. Optimum percentage saccharification of newspaper at an incubation temperature of 50˚C, after ten consecutive incubations, was 64% with lower percentage values of degradation obtained at 60ºC (59%), 70ºC (42%) and 40ºC (54%).

The saccharification of newspaper by various cellulase enzymes such as obtained from Trichoderma viride [15] and Penicillium funiculosum [16] as well as degradation of other paper materials such as office paper by Bacillus velenzesis cellulase [17], filter paper by Hypocrea jecorina cellulase [18] and magazine paper by Ruminococcus albus cellulase [19]. Newspaper is not the only waste cellulose material which could be developed as a resource of renewable feedstock as garden and kitchen waste [20] as well as agricultural waste [21] have also been classified as waste cellulose with the pontential to be developed as a suitable substrate for the production of bio-products.

With an increasing global population, the pressure on natural resources will increase and similar would be the case with the management of increasing volumes of solid waste. The development of the cellulose component of used paper as a resource and feedstock for bio-energy development would not only contribute to improve efforts for conservation of the environment, but could also act as a model for other waste paper materials as well as substances classified as waste cellulose to be developed as a renewable feedstock for bioenergy based synthesis. Also of importance is the search for alternative cellulase enzyme systems, such as cellulase recently extracted from garden snails, that could be more effective in the degradation of cellulose [22].

Conclusion

Used newspaper is a major component of solid waste and is mostly managed by incineration and landfilling

with uncontrolled dumping of this renewable material often visible in densely populated areas. The

chemical composition of newspaper is a suitable resource for renewable development procedures as has been

confirmed by A. niger cellulase enzyme action on newspaper whereby fermentable sugars are produced. Also

of importance is the similar general degradation pattern of newspaper when bio-converted into sugars at

different incubation temperatures thus confirming the relative contribution of amorphous and crystalline

sections of cellulose present in newspaper. The effect of temperature is also concluded by this investigation as

it is indicated that a low temperatures does not supply enough activation energy for the process while higher

temperatures could cause structural changes in the enzyme resulting in less production of sugars during the

saccharification process.

As the conservation of the environment is important, the development of newspaper as resource of renewable development, will not only limit the amount of solid waste but also limits the reliability on fossil fuels as feedstock for the synthesis of many chemicals, bio-chemicals and pharmaceuticals products. The saccharification of newspaper is also environmental friendly as it is performed with a biological catalyst at relative low reaction temperatures, which requires a low energy input for the process, that is a variable with a less negative effect on the environment. Instead of landfilling thus occupying valuable land or incineration producing dangerous gases, used newspaper could be developed in an environmental friendly manner as a resource for the development of environment benign chemical substances.

Bibliography

Hi!

We're here to answer your questions!

Send us a message via Whatsapp, and we'll reply the moment we're available!