Biography

Interests

Maryam Miryousefi Aval

Department of Occupational Health Engineering, Faculty of Health, Mazandaran University of Medical Sciences, Sari, Iran, Zip Code: 48175-16548, P.O.Box: 48471-1553, E-mail: Onemmblue@Gmail.com, Sari, Iran

*Correspondence to: Maryam Miryousefi Aval, Department of Occupational Health Engineering, Faculty of Health, Mazandaran University of Medical Sciences, Sari, Iran.

Copyright © 2019 Maryam Miryousefi Aval. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

In recent years, experts have come to the conclusion that development and development are valuable

in development projects that do not have health, safety or environmental hazards. In this regard,

environmental issues at the international level such as the Rio de Janeiro Conference were considered

by experts and politicians. In Iran, like other countries in the world, the issue of environmental

protection and its compliance with the first program of economic, social and cultural development

of the Islamic Republic has begun and expanded in the future. In this regard, new perspectives are

being introduced that will bring about dramatic changes at various levels of planning, processes and

specialized sectors such as civil, industrial and educational sectors. The training of engineers in this

regard can play a very important role in refining the attitudes of young engineers and using these

bases in their specialized activities. One of the important tasks of universities is to provide a suitable

platform for such training. In this regard, it is essential that the major industrial universities of the

country develop various programs in this field.

The present study is a review of the type of validity that is performed through search of authoritative

scientific databases such as PubMed and Scopus, Google scholar, PubMed using the key words of

building safety and health, HSE, and prevention methods are the latest information.

Implementing the principles of HSE in various construction, industrial and other projects requires

time, because any change that is considered in the system requires a change of attitude, which in

turn requires time to adapt and adapt to the new conditions. The conditions for the projects in

this research are their current conditions, and the next research, after a while, can determine the

percentage of project progress in terms of HSE.

In order to comply with the principle of HSE cases, there is a need for training. These trainings

should be executed at different levels and levels of contracting and monitoring so that the level

of awareness of the risks involved in the development of civil operations between the personnel

reaches a common frontier.

Introduction

In recent years, experts have come to the conclusion that development and development are valuable in

development projects that do not have health, safety or environmental hazards. In this regard, environmental

issues at the international level such as the Rio de Janeiro Conference were considered by experts and

politicians. In Iran, like other countries in the world, the issue of environmental protection and its compliance

with the first program of economic, social and cultural development of the Islamic Republic has begun and

expanded in the future [1,2].

In this regard, new perspectives are being introduced that will bring about dramatic changes at various levels of planning, processes and specialized sectors such as civil, industrial and educational sectors. The training of engineers in this regard can play a very important role in refining the attitudes of young engineers and using these bases in their specialized activities. One of the important tasks of universities is to provide a suitable platform for such training. In this regard, it is essential that the major industrial universities of the country develop various programs in this field [3,4].

The HSE management system is a management tool for controlling and improving health, safety, environmental and quality issues. This management system, by simultaneously examining the three factors, provides a good basis for the establishment and implementation of environmental management standards (ISO14000), Occupational Safety and Health Management (OHSAS18001) standards. According to researches carried out in this field, attention to the principles of occupational safety and health and observance of these principles has played a major role in reducing the economic losses of industrial units. Because with the reduction of accidents, the possibility of damage to the equipment and the loss of financial losses and the reduction of personal injury will occur. The incidence of any incident even includes very small losses that are classified as either direct or indirect losses or indirect or hidden losses [5-7].

After the inspections carried out in various construction projects, due to the diversity of work and the various stages of its implementation, some conflicts were found in the various sections of safety, health and environment in general, which are common to most projects, and below We will talk about it.

In this research, development projects were considered, which included the construction of tunnels, highways, bridges and underpasses. There are various activities in terms of safety, health and environment in these projects that are mentioned below:

The commencement of construction work will be carried out only after the construction permit is issued,

which includes installing and installing structural members, concrete structures and other measures, as

detailed in the 12th National Building Code [11]. Meanwhile, the owner, owners and stakeholders as well

as contractors and mass makers are required to take the following actions in order to maintain and ensure

public safety:

1. All natural or legal persons shall be responsible for the implementation of the safety regulations and the protection of the incident during the conduct of the work or operation.

2. The owner or operator or contractor shall provide and provide the necessary equipment and equipment to protect the health and safety of the workers at the workplace, and shall monitor the use of the equipment and observance of the regulations.

3. In the event of an accident or collapse of a building under construction or being demolished, the owner is obliged to stop work immediately, to take workers away from work and to deal with the risk.

4. Blocking or limiting sidewalks, public passages and other public facilities for the storage of materials or construction operations, subject to the following:

(A) Equipment, materials and construction materials should be placed in such a place that there were no accidents for pedestrians, vehicles, public facilities or adjacent buildings. Necklaces should also be identified with brilliant signs and red lights.

(B) In cases where the scaffolds are located in public passages, it is necessary to prevent the displacement and movement of its foundations by means of effective means.

(C) When following a construction activity hazardous to the movement of pedestrians or vehicles in doubt, the following shall be complied with:

1- The placement of one or more guards with a warning sign

2- Installation of flashing lights or shadow marks

3- Installing informative signs and track control devices

4- Creating Enclosure Protective Structures

(D) On drill rigs on public roads, a temporary bridge of pedestrian crossings must be created with necessary resistance and, if drilling on the street, it should be temporarily created to provide sufficient resistance to vehicle traffic.

(E) All cliffs in the construction workshop, the surrounding area and public areas where there is a risk of falling people should be covered by the final enclosure or the installation of permanent and main protections and fences by means of protective coatings or fences Tightly fitted and temporarily protected. Also, if there is a risk of the fall and falling of the tool of work or building materials, then proper installation of the foot should be done.

And (ii) excessive safety loads on any skeleton, wood scaffold, shield, fencing, temporary covering, overhead cisterns, passageways and the like are not permitted.

1. All stairs - platforms - and heaps must have sufficient strength and bear the pressure and heavy loads of ordinary loads.

2. Stairs and platforms made of latticework, the dimensions of its springs should not exceed 25mm, so that

various objects cannot fall.

3. The width of the stairs, with the exception of service and relief stairs should not be less than 90cm in any

case.

4. The difference between the two peaks should never exceed 3.7m.

5. The propulsion units located at stairways must have an area of about 1.10m in the stairs or more in proportion

to the stairs.

6. Throughout the steps, a free vertical distance at the height of the human should be taken into account.

This distance must not be less than 2.20m from the level of each step along the stairs wall.

7. Except service or relief staircases, the width of each step without computing its margin or bulge should

not be less than 33cm and the height of the stairs is between 14 and 20cm.

8. All stairs should be protected from the abyss by stairway fences.

9. Stairs that are more than 25/2m in width must be equipped in addition to the fences with a central fence.

10. The height of the stair rail fences from the edge of each step should not be less than 75 centimeters and

if these fences are used as hand fences, its height should not exceed 85 centimeters.

11. Entry of windows that open in stairs, if they are more than 30 centimeters wide and the distance to the

surface of the parcel is less than 90 centimeters, must be protected by fencing.

12. The maximum allowed gradient for (steep corridors) is 10 degrees. These ramps must be in line with all

the conditions for stairs, in terms of building, width and fence, and so on [12,13].

1. In each building workshop, the employer is required to take the necessary measures to maintain and ensure

public safety.

2. Each employer is responsible for providing and providing adequate lighting in public spaces, providing fences and vaults, and installing them around open ceilings and open walls and open spaces, providing and installing fencing and protection around stairs and potholes, creating safe entry for a workshop. And workplaces, providing firefighting equipment, providing safe drinking water and providing health services, providing personal protective equipment and initial assistance, and, in general, providing and securing public safety conditions within the workshop.

3. Every worker must provide and maintain the necessary tools and equipment for carrying out construction work by the workers, in accordance with the material of this section, in order to provide workers with the necessary time and provide them with the necessary training. Use those devices correctly [14].

4. Construction operations must be planned and implemented in such a way that the potential risks arising from it, inside or outside the workplace, can be prevented as soon as possible. In the event of a risk of life, the employer is obligated to immediately stop work and remove workers from the location of the incident. The employer must ensure that any work-related incident occurs during normal or daily work hours at the workshop as soon as possible and before the related signs and symptoms have been eliminated to the relevant units in the Ministry of Health and Social Work Notify the location.

1. All permanent and temporary buildings and institutions subject to the provisions of the Labor Law must

be fully constructed from a structural point of view, and the following points should be Considered in calculating

the base, ceiling and floors:

A. Tolerance of the pressure due to the maximum loads and fixed and moving objects.

B. Pressure from snow, rain, frost, wind and storm.

C. Bearing pressure from suspended loads.

1. Rooms and permanent work space must be at least 3 meters from the floor to the height of the roof and

its space must not be greater than 12 meters for each person for the maximum number of people working

there. In calculating space cubic meter, the volume occupied for furniture, machinery, materials and supplies

is not deductible. In buildings where the height of each floor exceeds 4m from the work space, it is calculated

and calculated to only 3 meters in height [15,16].

2. In the workshop room, the installation of machinery or the placement of objects and products should not

interfere with the transit or work of workers. Approximately enough space must be provided around each

device so that workers can easily go about normal tasks and, if necessary, make corrections and repairs of

materials or materials.

1. The floor of the rooms and areas which have been assigned to the workers’ passage or for the transport

of materials shall be smooth and shallow, free of holes and holes, wood chips, buckling due to inadequate

hinges, nails and screws, and nuts and tubes A gate or a bulge, and any obstacles that may cause the person

to catch or slip [17,18].

2. The floor of the rooms and corridors and sidewalks shall not be slippery under normal conditions, nor shall

it be made of materials or made of materials that could lead to dust, dust, and slipping, resulting in slippage.

3. In the workplace and in the places where multiple devices are located, they must be specified by a specific

color on both sides of the main road and the subways, and even the location of the raw materials and

materials produced by these lines is determined until the commute, Transportation of materials and also the

direction of the main movement with the marking on the ground is clear and clear.

4. Floor workshops should be washable. In cases where the type of work leads to the discharge of water in

the workshop, there should be a sufficient slope to direct the water towards the drainage channel.

5. Workshops should always have favorable conditions for ventilation and provide a healthy climate for

workers.

Material and Methods

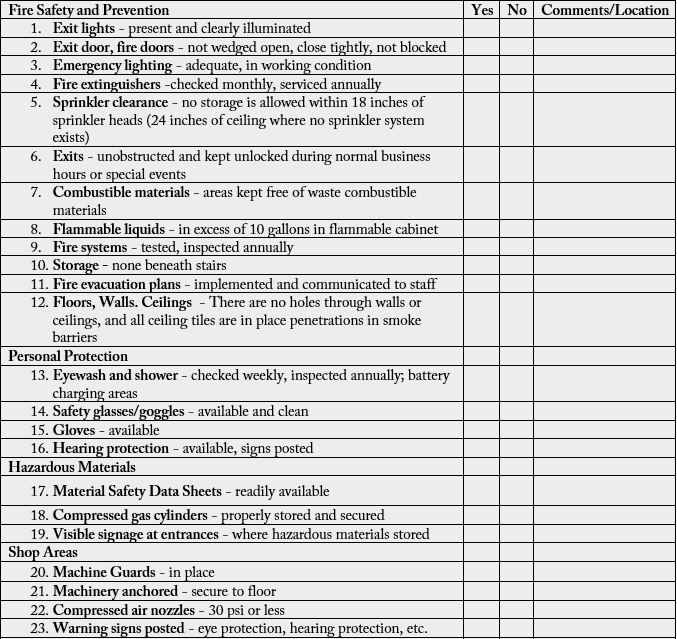

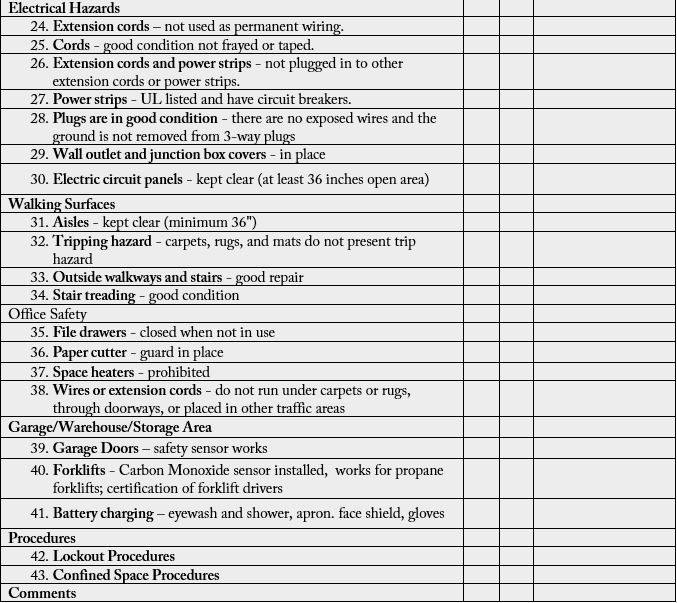

Collect and summarize information from databases PubMed and Google Scholar. Articles research and

review using MeSH pattern from: Safety for Buildings, HSE, OHSA, ISO and WHO. Also, according to

the standard safety checklist, the necessary information was collected.

The aim of our vast building safety services is to improve the overall safety and efficiency of your buildings

and the systems and products you operate within them. Our highly qualified engineers, technicians and

expert witnesses perform all manner of testing, assessment and evaluation of industrial systems and equipment

against the background of a wide variety of requirements. Naturally our engineering services adhere

to all technical and legal regulations, however, we also place great importance on maintaining the standards

agreed with contractors without losing sight of cost-efficiency. Whether initial acceptance inspections, repeat

testing of technical systems or a safety concept for the facilities: DMT ensures the necessary safety in

a wide range of fields [19,20].

As an organization of the TÜV NORD GROUP, we carry out independent tests for a variety of industries and advise our customers on product safety, building safety and plant safety, for example in the fields of:

- Building maintenance

- Fire and explosion protection

- Air and water hygiene

- Ventilation, refrigeration and air conditioning technology

- Air quality

Benefit from transparent, competent advice and save high long-term repair costs: Damage caused by ageing

and wear on concrete structures cannot be completely avoided. With our condition assessments and preventive

maintenance inspections, however, you can prevent unplanned plant downtimes and safety defects in good

time [21].The early recognition of maintenance requirements can save you cost-intensive repair bills further

down the line. With our surveys you can also ensure that operating licences are obtained and an exact budget

plan is drawn up: our independent specialists check the structural condition of your building visually, metro

logically and by way of sampling and make recommendations for maintenance or repair. You will receive

our expert opinions and recommendations in accordance with the applicable standards and regulations. We are certified by the German Association of Material Testing Institutes (VMPA) as a recognized concrete

testing center for the determination of compressive strength, flexural strength and water impermeability, on

moulded test specimens, and compressive strength on drill cores [22].

• Investigations on fresh and hardened concrete in plants, on construction sites or in the laboratory, analysis

and interpretation of the results from a single source

• Assessment of the condition of existing buildings and engineering structures according to DIN 1076

• Manual inspection: concrete condition, concrete corrosion, reinforcement corrosion, joint condition, joint

sealants

• Core drilling and non-destructive testing methods

• Testing of aggregate, cements, mortars and screeds

• Concrete chemical investigations

• Assessment of water and soils aggressive to concrete

• Concrete tests: cracks, reinforcement corrosion, white tank

• Testing the compressive strength and water permeability of concrete test specimens

• Advising the company and the construction sites on concrete selection and processing

• Performance of suitability tests, quality and hardening tests

• Evaluation of concrete tests

• Inspection of the equipment of the construction sites and specialist training

Compliance with these requirements is required in all construction work that is to be cut and welded. Hot

and flammable materials. Safety in construction in all places where there is a danger of fire, smoking is

prohibited, and the symbol for “hazardousness” Do not smoke “in these places. The burning of any kind of

rubbish, scrap and other combustible materials and the like is prohibited unless authorized by the competent

authorities. The collection and storage of oil, grease, oilseed rags and oil-contaminated rubbish and oil

products, etc., are not permitted on or in the vicinity of construction equipment [23].

All permanent or temporary immersion heaters must be properly installed, so that the walls and wooden parts are less than one meter away, and the carvings and the like are not less than 3 meters apart. Combustible liquids and the like before refueling, the engine must be turned off and the fuel cannot be thrown out of the exhaust and the engine’s hot part.

All liquids with a flare point below 7ºC should not be stored on the surface of the earth unless they are limited to containers or reservoirs. The exhaust and fuel tanks shall not be emptied of where the storage or disposal of the tanks on the engine, exhaust, switchgear and all electric and battery, or other sources of sparking, are spilled. Where flammable liquid vapor is present, spark plugs, such as cigarettes, cabinets, gas, lights and other appliances should not be used [24].

As long as there is temporary use of heater or any open air heater at work: all relevant regulations and

regulations, such as maximum temperature, heating distance to combustible material, exhaust gases, as well

as other items declared by the competent authorities is adhered. When using temporary heating elements,

adequate ventilation should be provided. The temporary heating device during use should be placed securely

on the floor so that there is no possibility of overturning. In addition, suitable fire extinguishing appliances

should be in place. The place is available. When using liquid gas for heating temporary work areas, the gas

tank should be placed outside the building and in the open space. Cooking bitumen and asphalt of barrels

and boilers for cooking bitumen and asphalt during use should be tight in place, so that during work there is

no danger to people. Barrels and boilers for bitumen and asphalt should be placed outside the building and

outdoors, placing them in public passports without the permission of the official building of the building is

not allowed.

When working with boilers for bitumen and asphalt, appropriate firefighting equipment must be available. Containers containing hot bitumen should not be stored in the enclosure, unless part of the enclosure is open and ventilation is performed completely and sufficiently. Workers engaged in cooking bitumen and asphalt should be equipped with gloves and forearm protection. The lifting of asphalt or hot bitumen by the worker from the ladder is prohibited [25].

All boilers that are used temporarily or permanently must be installed and installed by competent persons

and subject to the provisions of the heating and cooling installation.

Before starting welding or cutting operations, all pressure and flow control devices and the like should be

monitored. Protective equipment, such as masks, shields and liches, should be used to protect spark, radiation

and other combustible materials. If the cutting and welding operation is in the vicinity of the flammable

material, an auxiliary person must be present at the same place while providing adequate firefighting

equipment. When welded on metals that cover tin, zinc and the like, it is necessary that the smoke from the

welding is quickly directed away from the workplace. In order to prevent the risk of explosion of oxygen gas

cylinders, the valves and fittings should be kept away from oil and grease and workers should refrain from

handling oxygen gas cylinders and joints with oil or lubricants contaminated by hand [26].

The valves of these cylinders must be opened with a hand and without the use of a hammer and a wrench,

and if necessary, use special wrenches. Cylinders that are not in use should be placed in an open space outside

the building to protect against direct sunlight or high temperatures as well as impact. The cylinders should

not be thrown from any height. In addition, it is necessary to use special coils to raise and lower them. The

gas cylinders must be spaced sufficiently from the place of welding and cutting, so as not to spark, bridle, or

flame.

Until deformable concrete blocks from the building being built are not to be stored, there should not be any

combustible materials. Storage of flammable materials: Storage of combustible materials, oils, paints and

other flammable materials must be carried out in compliance with the fire protection regulations (Section

III of the National Building Regulations of Iran).

Combustible waste and garbage: Combustible waste and rubbish should be collected in appropriate place and taken out of work in the newspaper to the authorized place. The burning of waste and rubbish at the site of the construction workshop is not permitted.

A: In order to prevent the risk of electric shock and to increase the level of safety of individuals and reduce

the physiological and human waste and protect public facilities, the rules and regulations for the transmission

and distribution of power lines for all construction operations must be observed. All temporary and

permanent wiring and installation of electrical equipment should be carried out in accordance with the

provisions of the design and implementation of electrical installations of buildings. Prior to digging, measures

should be taken to protect and isolate high-pressure lines. High-pressure lines are all lines containing

electricity at 0001 or higher.

T: In places where strong pressure lines exist, the repair and installation of electric and wiring equipment and equipment for temporary use is not permitted unless the power supply is interrupted or the operation above is in excess of the provisions of paragraphs 1-2-2.9. From 3 meters of lines and devices with high voltage current [27].

Buckets of water and fire extinguishers and other portable fire extinguishers must be installed and ready for

use in different parts of the workshop.

B: When fire pipes and gates are to be used as part of permanent building facilities, it is necessary, with the supervision of the competent authorities, to be installed and ready to be used, the distance between these pipes and lions to the street must always be located within two meters of the valves No blasting (fire extinguishing valve) or the distance between the lions above and the street should not cause any building material or waste.

In all construction workshops, the means of first aid and training of people in that field should be provided

in terms of type of work and in proportion to the number of workers, and the necessary steps should be

taken to transfer the damaged workers or workers who suffer from sudden illness into medical centers.

The first aid kit that has the necessary equipment declared by the relevant authorities should be installed in

the right place and kept free of any contamination and dust and always available to the workers [28].

Discussion

The basis of safety can be expressed in this important statement:

With regard to the issues discussed in the results section, it seems that in order to carry out work on development projects, according to HSE principles, it is necessary to consider some cases as a basis for observance of these principles. These include:

1. Culture: To ensure that the principles of HSE, in addition to preserving the life and natural resources, contribute to social development and development. These projects also require culture-building through various educational, written, spoken, visual and other methods.

2. Time: The implementation of HSE principles in various construction, industrial and other projects requires time, because any change that is considered in the system requires a change of attitude, which in turn requires time to accept and adapt to the conditions. New is. The conditions for the projects in this research are their current conditions, and the next research, after a while, can determine the percentage of project progress in terms of HSE.

3. Cost: Everything requires cost, and the higher the cost is, so it is guaranteed to work with high quality. Since the cost of complying with the principles of HSE has generally been seen so far, so it cannot be expected that all items will be done in a specific way. If the cost of the HSE is also considered at the beginning of the project, it can be expected that the items will be taken in principle.

4. Training: In order to follow the principle of HSE cases, there is a need for training. These trainings should be executed at different levels and levels of contracting and monitoring so that the level of awareness of the risks involved in the development of civil operations between the personnel reaches a common frontier.

Conclusion

In order to comply with the principle of HSE cases, there is a need for training. These trainings should be

executed at different levels and levels of contracting and monitoring so that the level of awareness of the

risks involved in the development of civil operations between the personnel reaches a common frontier.

Acknowledgment

We would like to express our special thanks to Dr. Rajendran for guidance on different areas of this paper.

Bibliography

Hi!

We're here to answer your questions!

Send us a message via Whatsapp, and we'll reply the moment we're available!